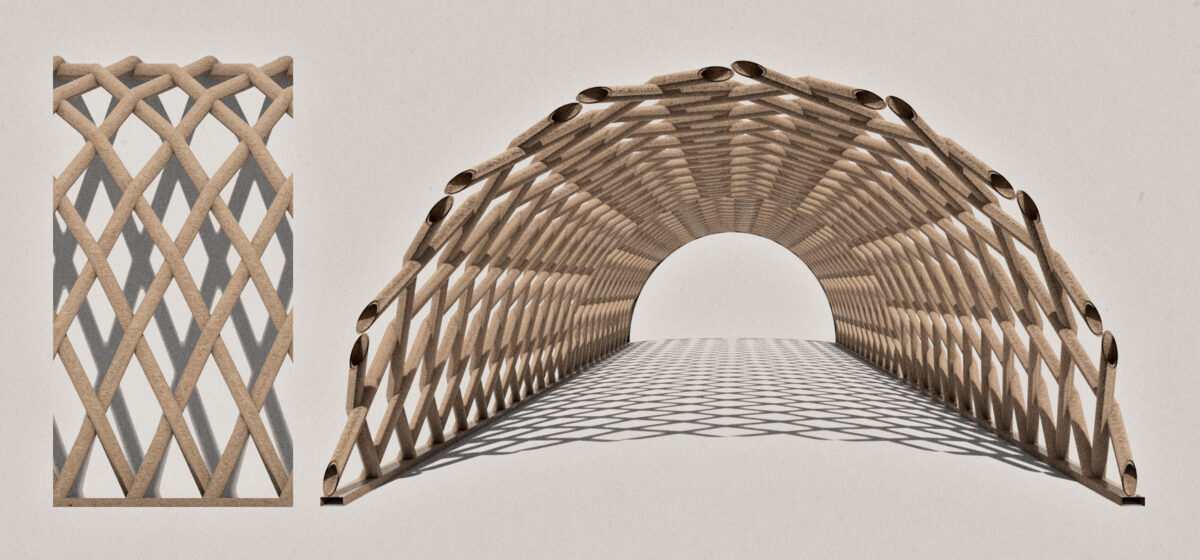

elements

Connection Methods

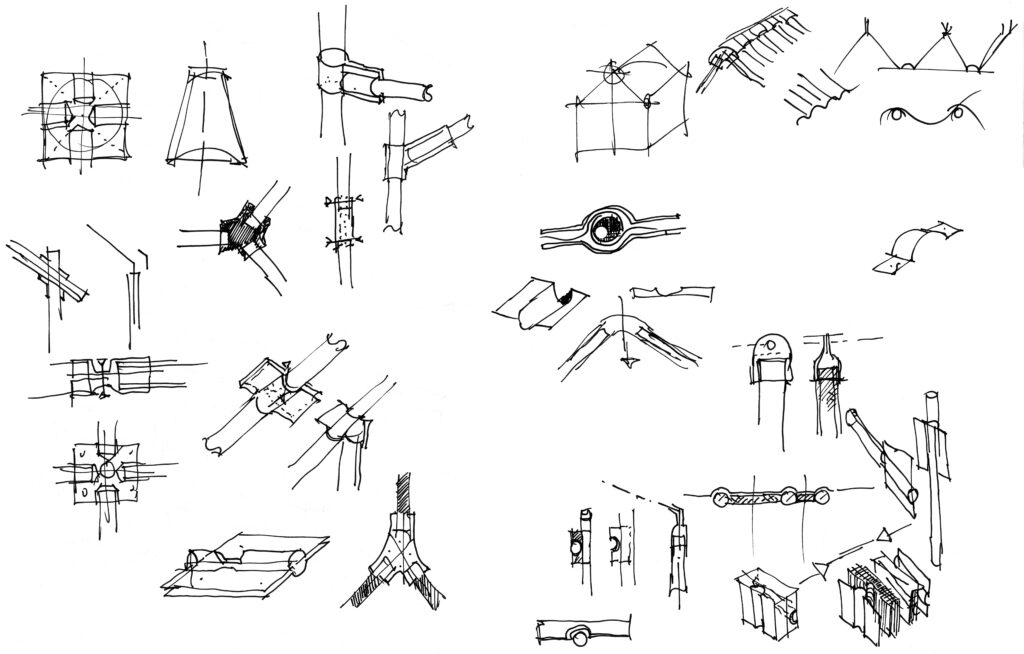

When dealing with paper and cardboard, the simplest processing methods are those that have long been established. The most obvious way to connect parts is to glue, press-fit, or staple them together, similar to what is done in small-scale projects or architectural model making. However, if paper is further developed to be used for building parts with increased material thickness, weight and volume, the connection methods cannot always be scaled up accordingly.

Gluing thicker layers of paper, for example, means that the increased weight could cause the layers to delaminate, introducing a new problem. We therefore need to search for new connection methods that advance the ones we know and incorporate new solutions.

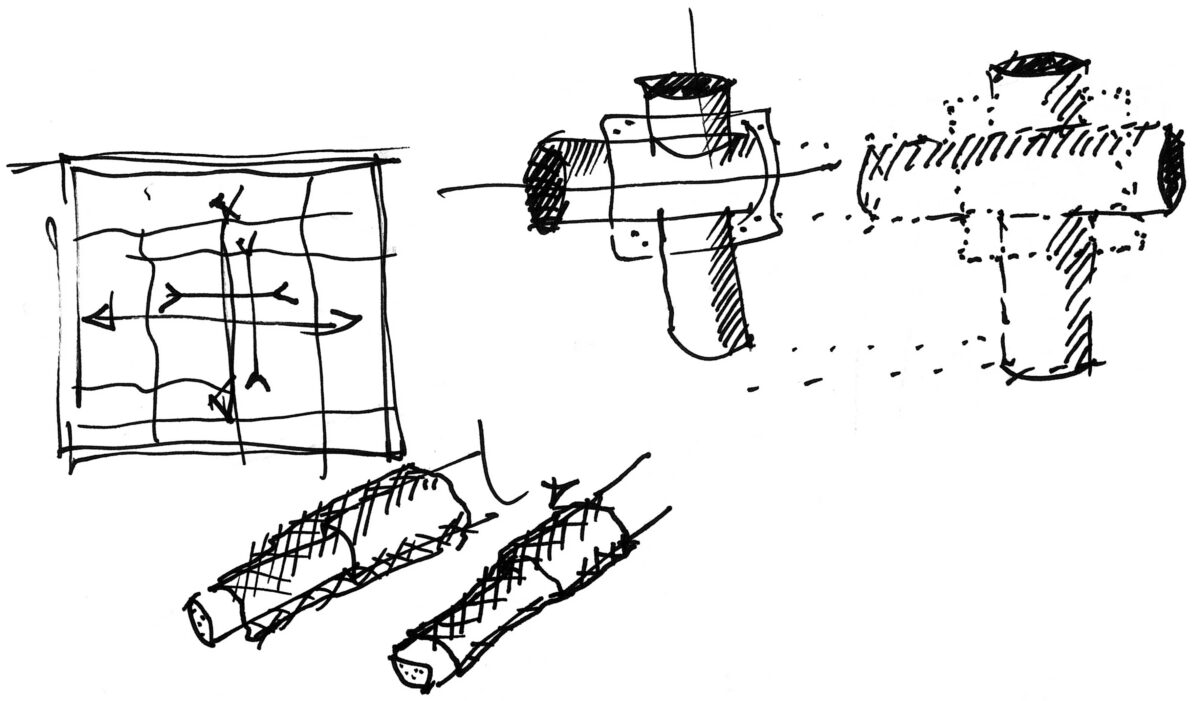

How can the structure of paper be adjusted; how can we exploit it to maybe connect

individual layers with each other?

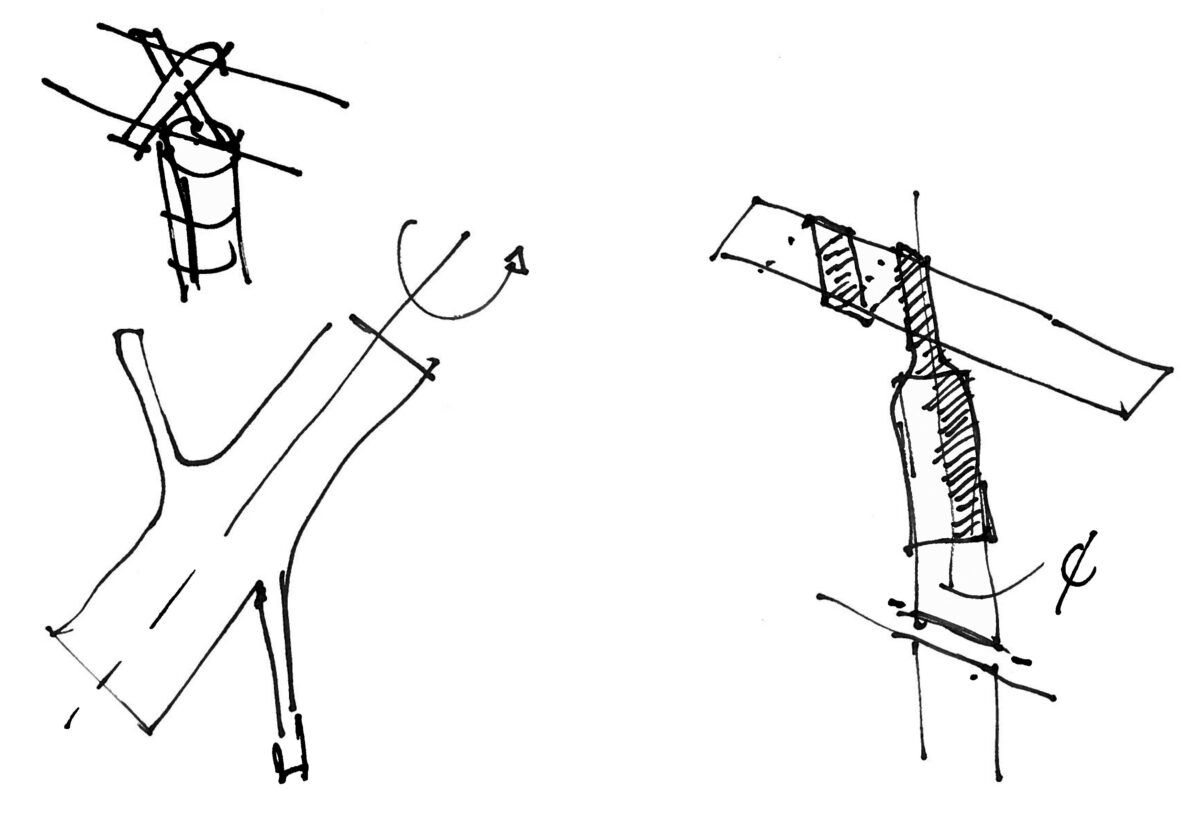

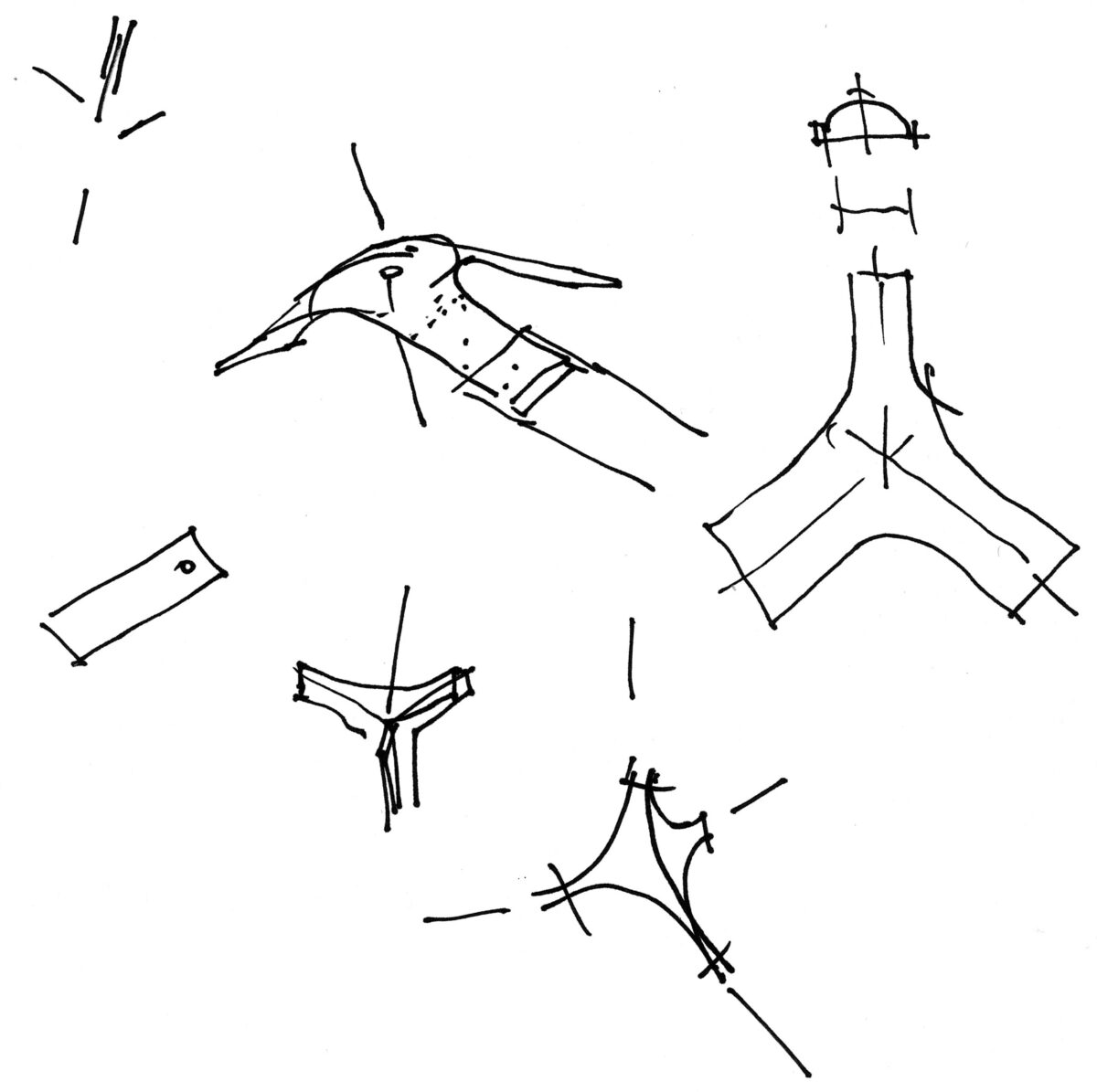

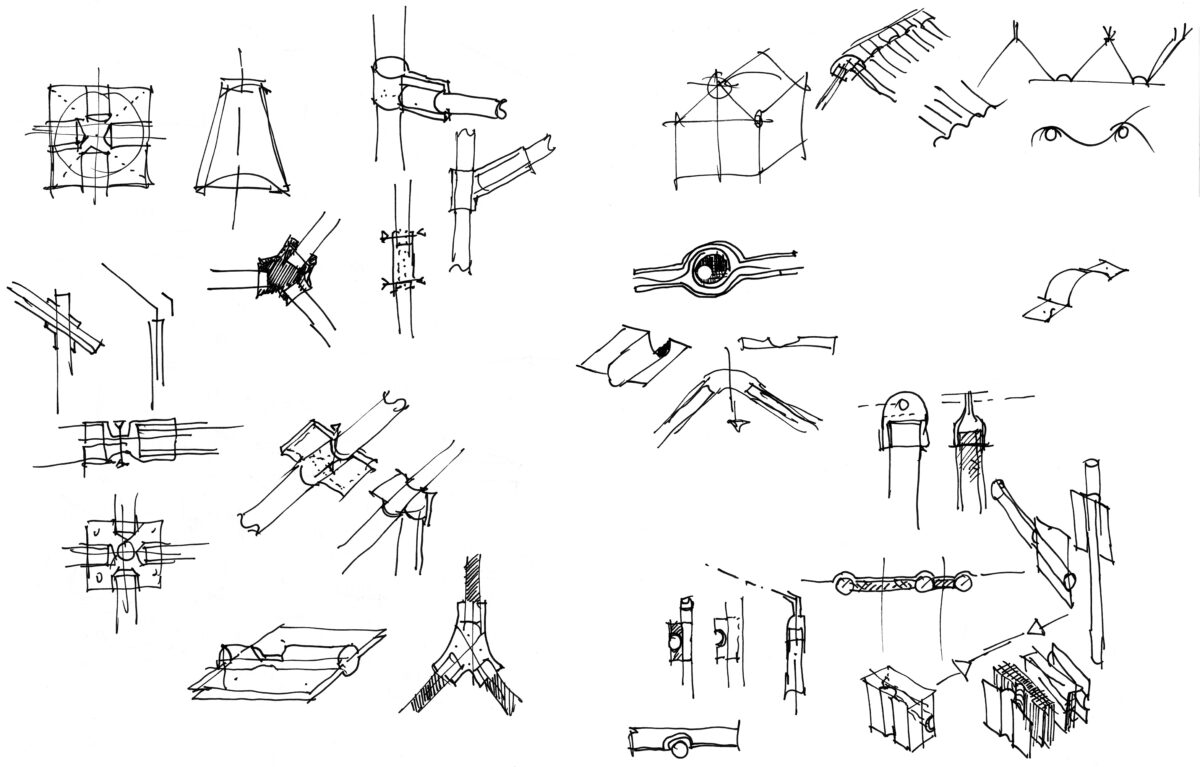

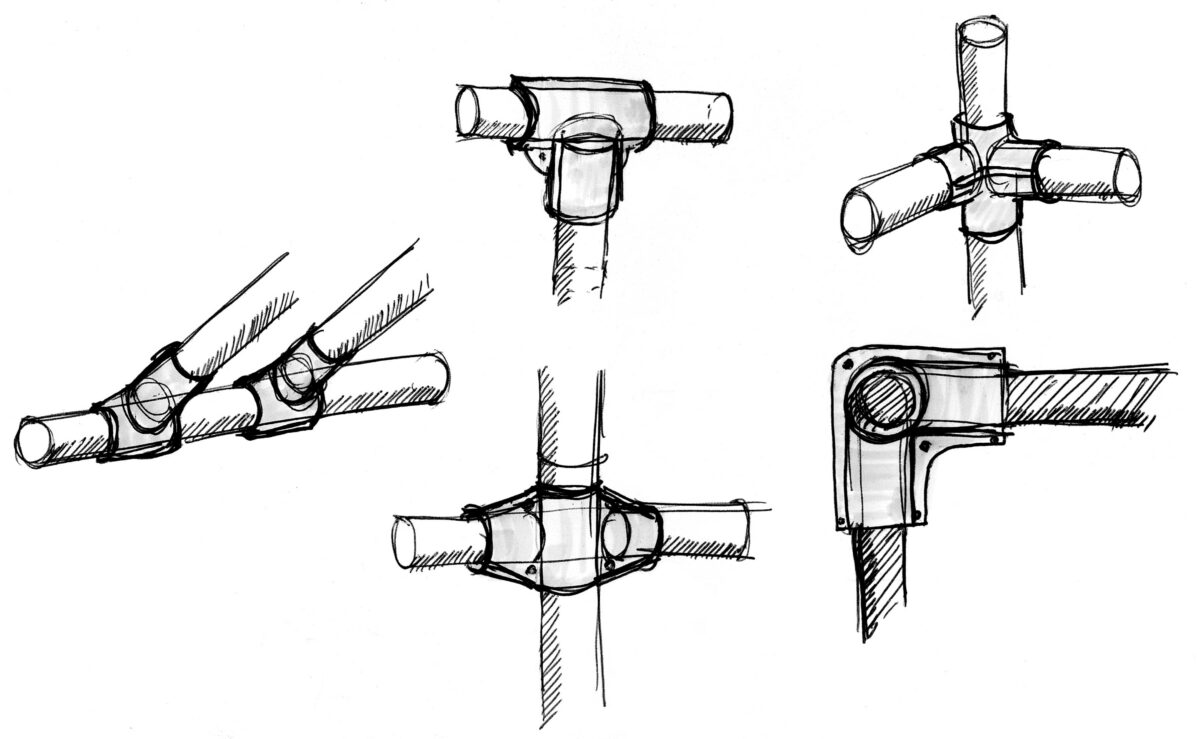

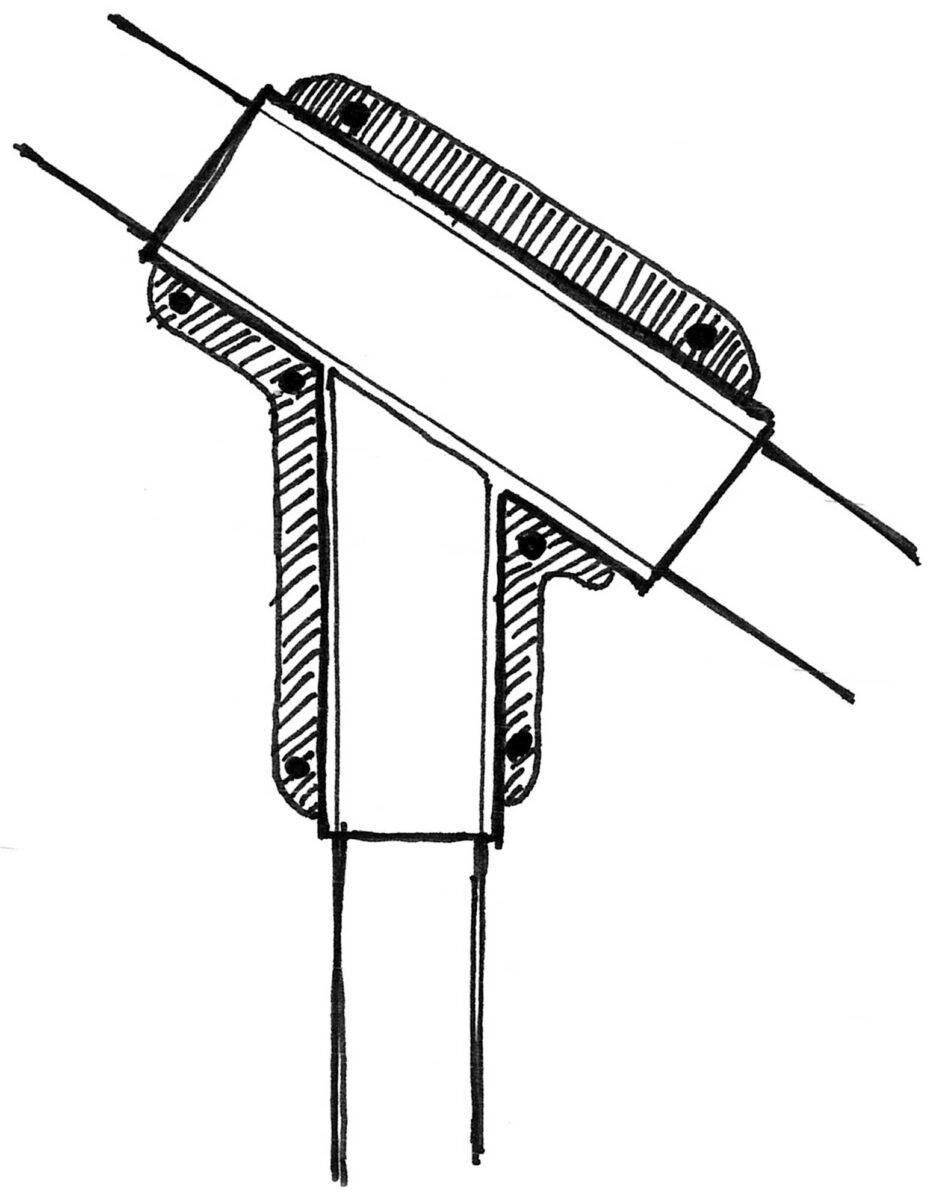

For example, by combining multiple layers with different fibre orientations at nodal points to connect the material. Can the nodal point of a support and a joist be fixated with a collar?

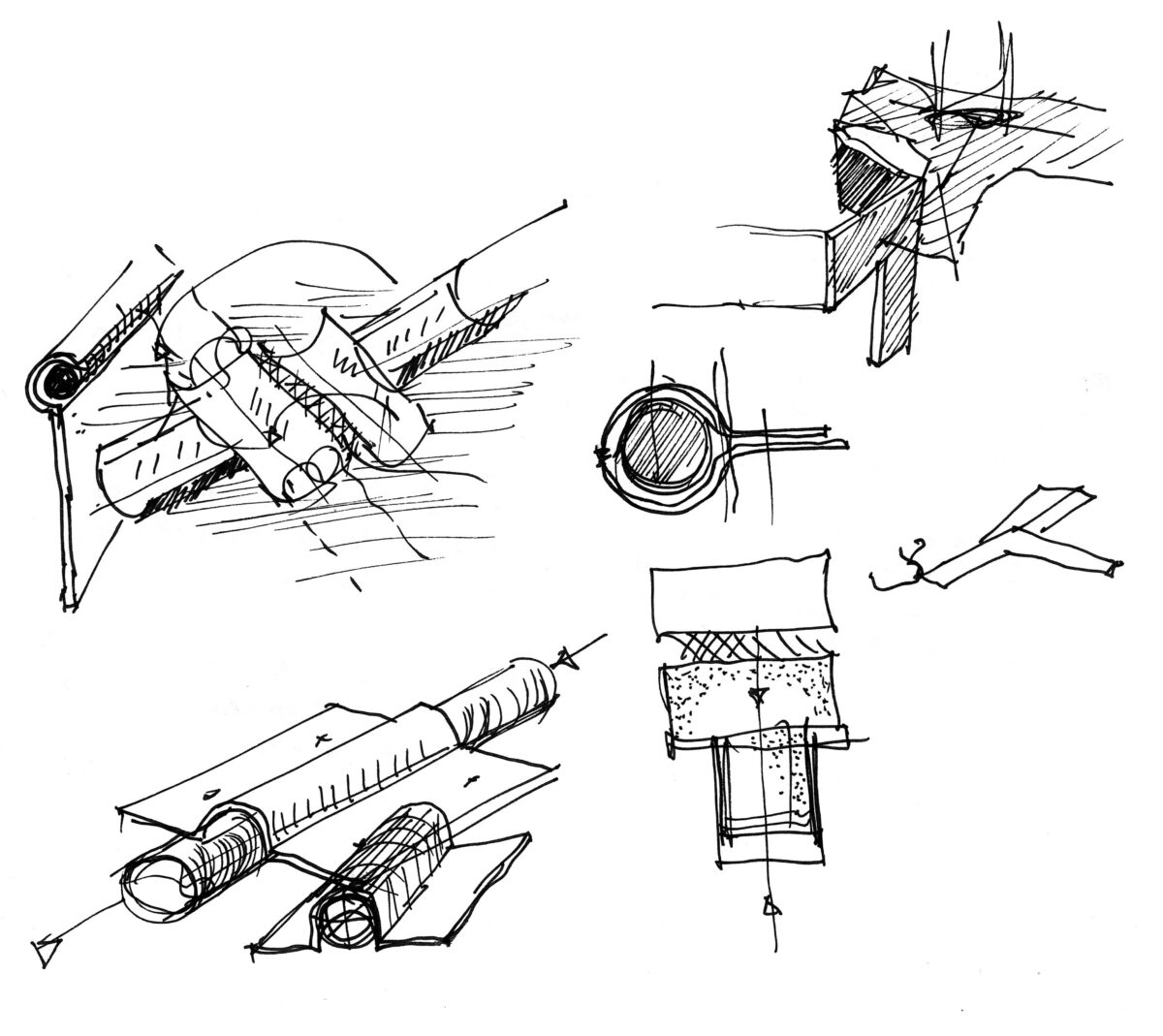

What happens if we apply glue to the collar, then put the collar in place when it’s still wet so that the fibrous structure of the material makes it wrap around the contours of the nodal point and therefore the construction?

If, in addition, the surface of the paper is such that two parts connect as a result of applying wet and dry processes to the fibrous material, this connection is a material-immanent bond without the need for additive materials. And it would mean that paper offers a potential that is a direct result of the specific material properties.

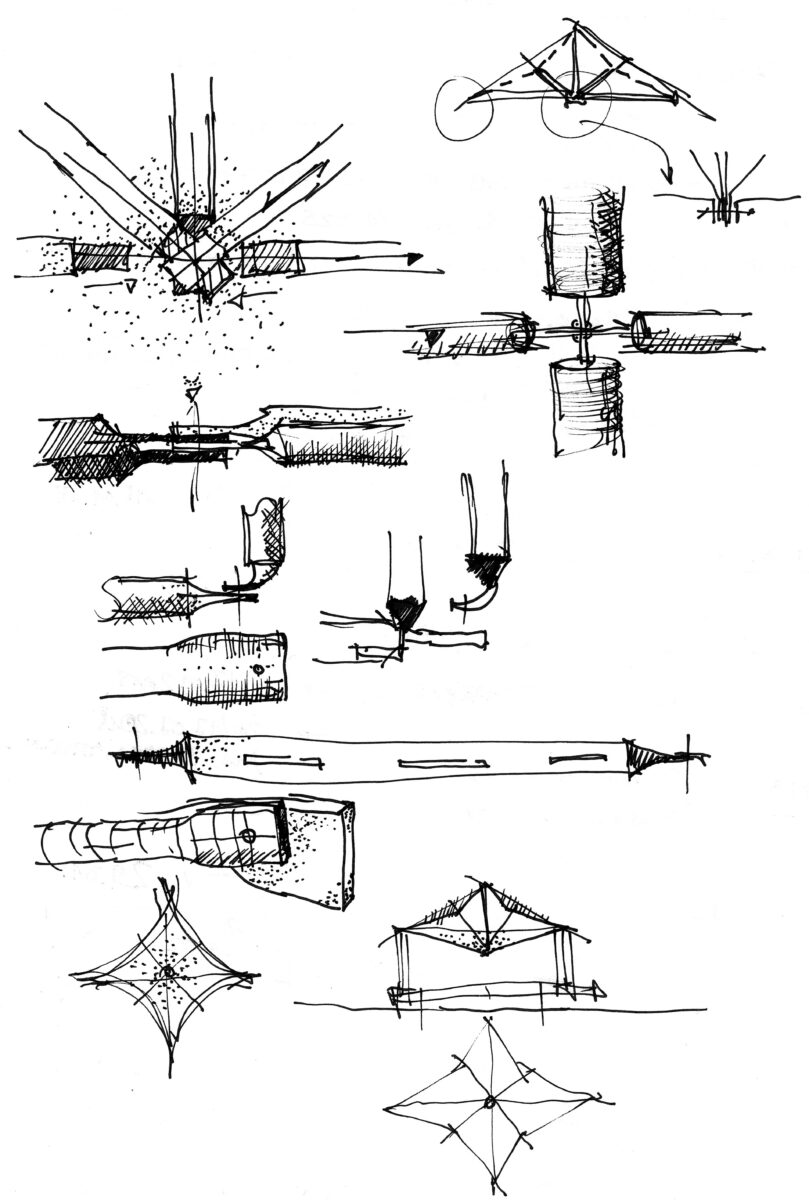

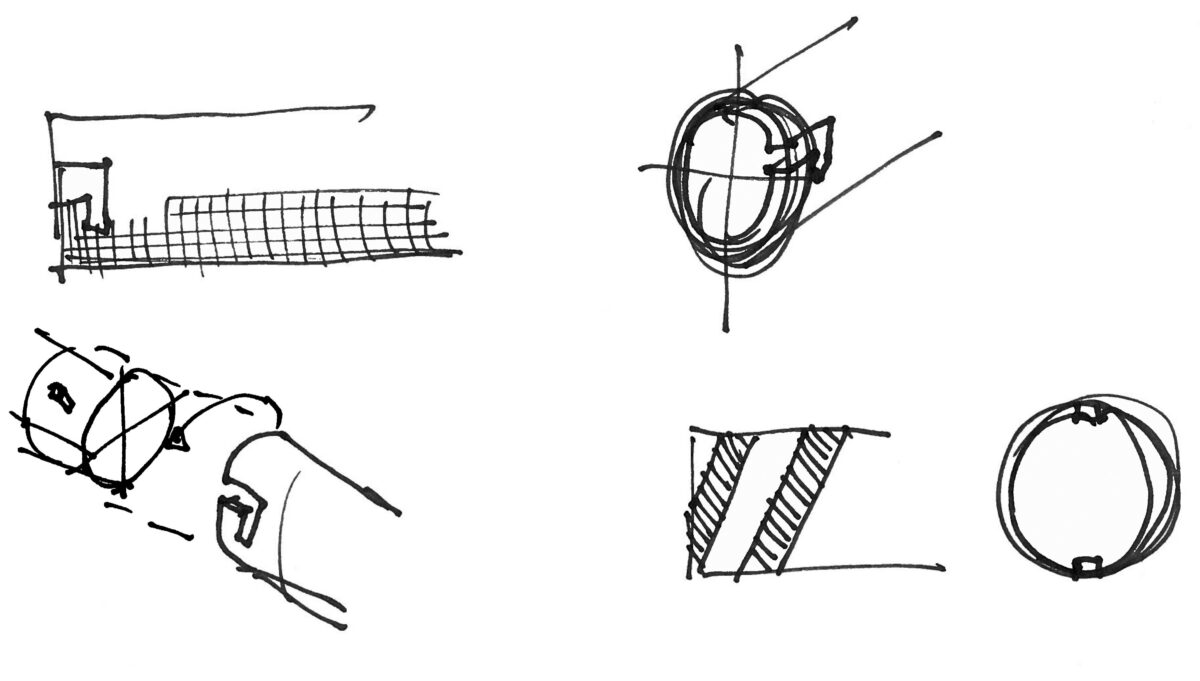

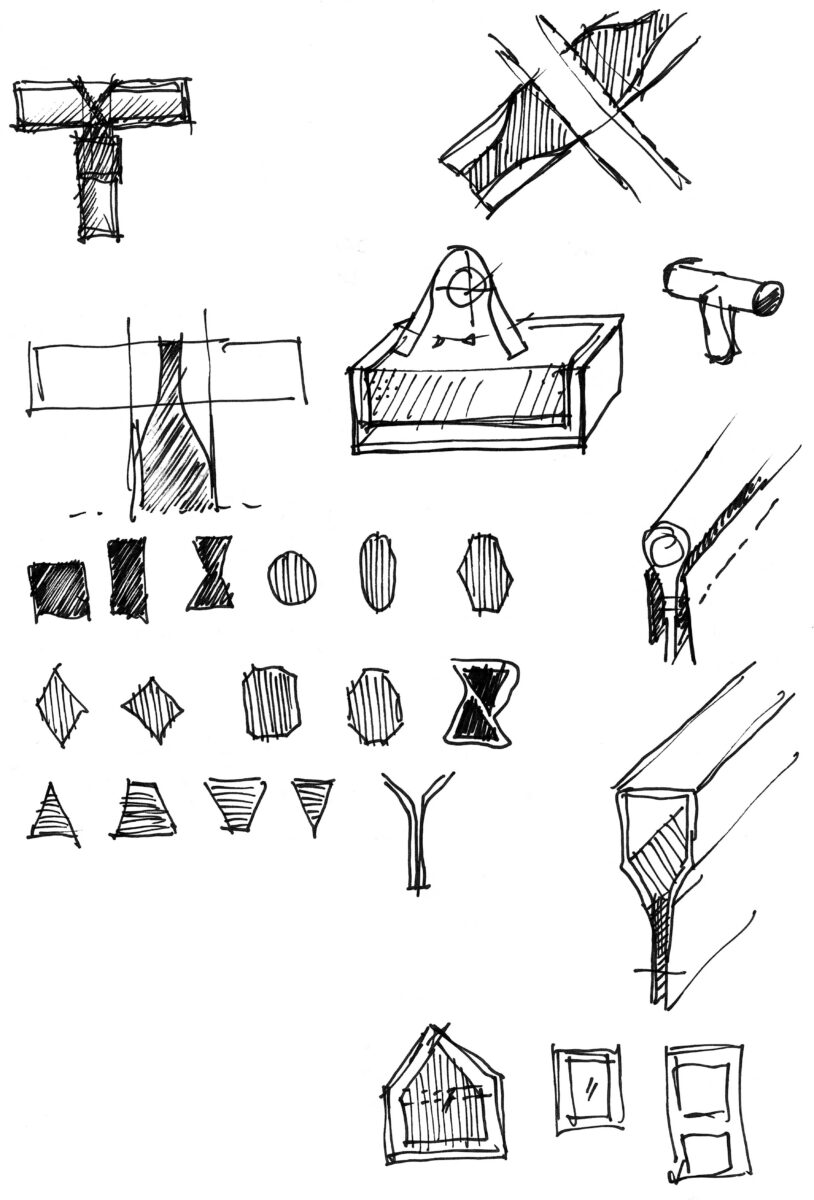

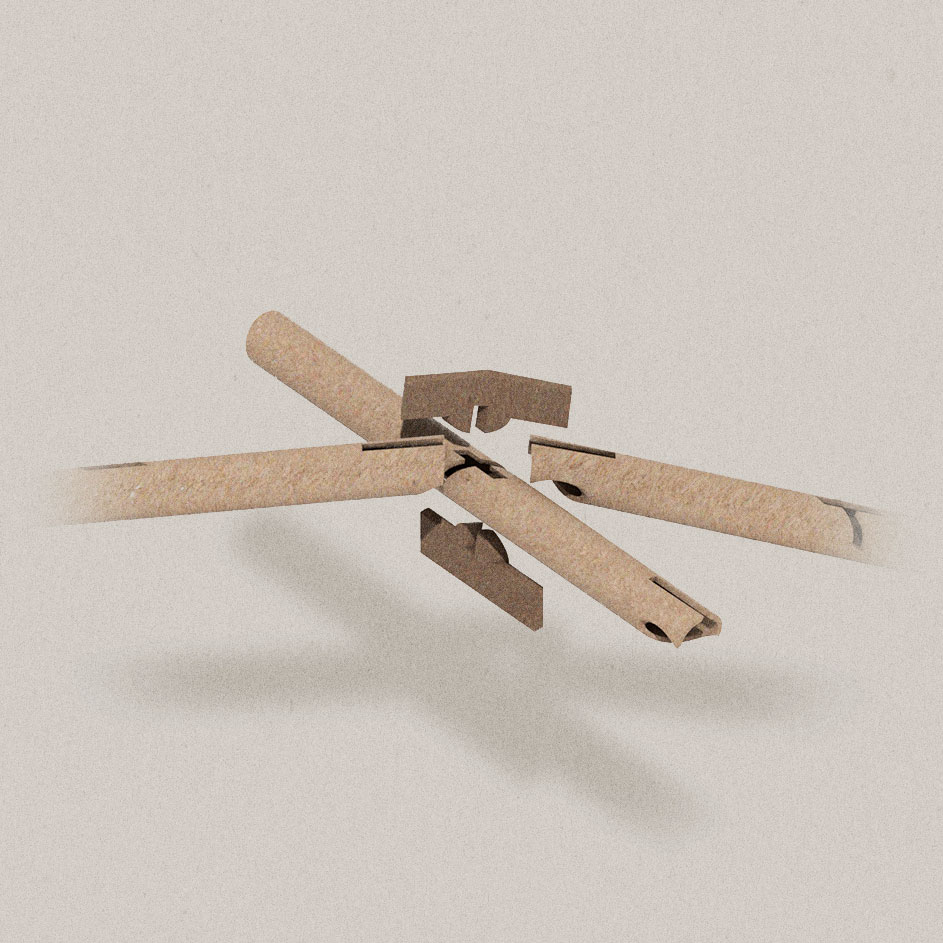

- Overview of various connection methods for paper and cardboard

- searching for material immanent joining

- joining of paper tubes